284/57 Ly Thuong Kiet, 14 Ward, District 14, HCM City, Vietnam

We do the best for customer!

284/57 Ly Thuong Kiet, 14 Ward, District 14, HCM City, Vietnam

8:30 am - 5:30 pm

07 Oct. 2024

Prefabricated houses are emerging as an ideal solution today. This is a fast construction solution that also saves significant implementation costs. It meets all requirements for flexibility and construction efficiency. This is not just a new trend in the construction sector but also opens up a sustainable future for projects of all sizes. Let's explore with KGM Vietnam!

What are Prefabricated Houses?

Prefabricated houses are a type of home built by assembling modules or structural components pre-manufactured in a factory. The house's components, including columns, walls, floors, roofs, and load-bearing frames, are precisely fabricated according to a predetermined design and then quickly installed on-site.

Thanks to the pre-fabrication process, construction can be completed in a short time while ensuring superior quality and durability. Not only suitable for residential homes, prefabricated houses are also widely applied in spaces such as: temporary structures, mobile offices, or public facilities like schools and field hospitals.

Applications of Prefabricated Houses

This model is currently widely applied in various fields, from residential housing to public projects:

Advantages of Prefabricated Houses

Not only favored for their flexibility, but they also offer many other outstanding benefits such as:

Time-saving Construction

Thanks to pre-fabrication in the factory, components only need to be assembled on-site, significantly reducing construction time compared to traditional houses. The construction of a house can be completed within a few weeks, instead of several months as with conventional construction methods. This is ideal for projects requiring rapid deployment, especially in emergency situations.

Cost Savings

Prefabricated houses help minimize many unnecessary costs by optimizing material usage and reducing on-site labor. The main stages are carried out at the factory, thereby limiting unforeseen issues such as material waste or extended construction time. Especially for large-scale projects, construction costs can be significantly reduced due to standardization and mass production.

Environmentally Friendly

They use recycled, environmentally friendly materials and minimize construction waste on-site. Furthermore, the swift construction process helps reduce noise and environmental pollution in the surrounding area. The use of materials such as recycled steel, composite plastics, and insulated panels also helps improve energy efficiency during operation.

High Durability and Safety

The components of prefabricated houses are manufactured to high-quality standards, ensuring consistency and safety. Because they are precisely fabricated in a factory environment, on-site assembly becomes easier and less risky. Additionally, they possess high durability and resistance to harsh weather conditions, meeting all construction safety standards.

See more: Living in modern architecture, engaging the senses with nature at Mystery Villa

Prefabricated House Construction Process

The construction process involves several stages, from site preparation and component manufacturing to assembly and project completion. Each stage is carried out meticulously, ensuring construction progress and quality.

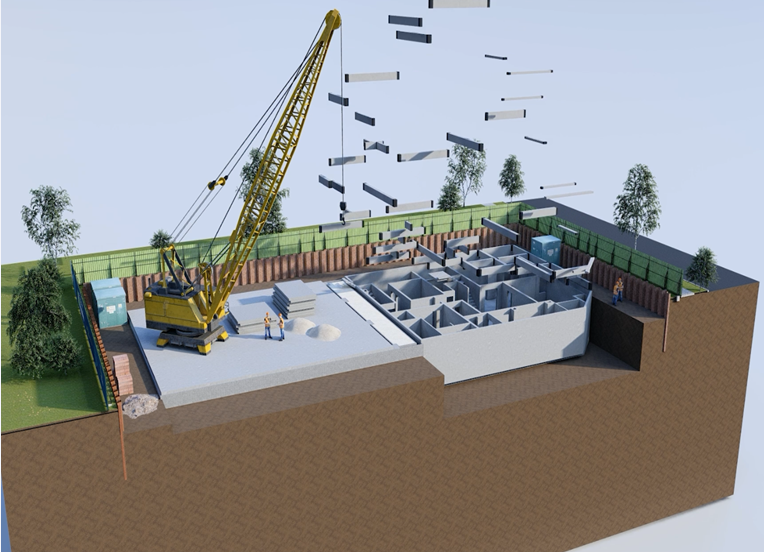

Stage 1 - Prefabricated House Basement and Foundation

Currently, the foundation is a very important part. KGM Vietnam still uses traditional methods for foundations, including pile driving, basement excavation, and soil retention in weak soil areas. This ensures that even on weak ground, the foundation quality matches that of traditional houses, while the remaining stages proceed with prefabrication.

This is the basement stage that KGM Vietnam has completed. On weak soil, earth retention protection and monolithic waterproof construction of the foundation, basement slab, and basement base are crucial. Specifically, embedding MEP (mechanical, electrical, plumbing) systems into the slab to connect systems for the prefabricated house from the ground floor upwards ensures quality.

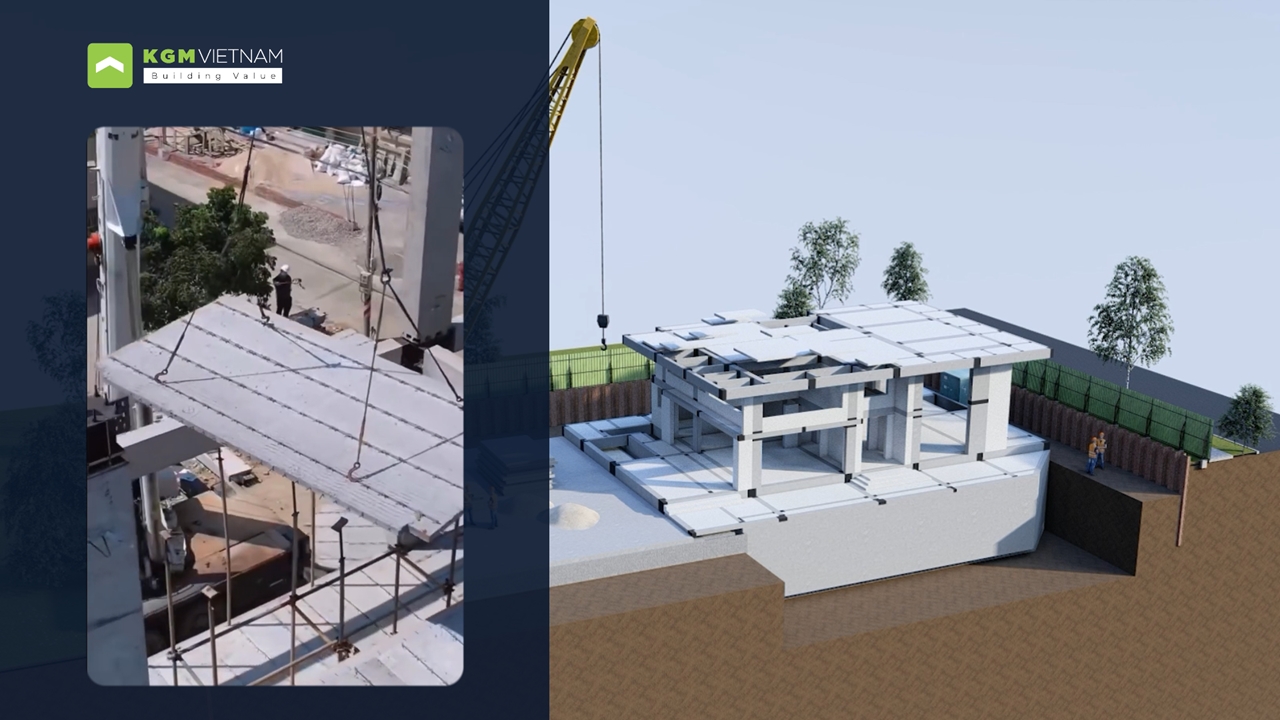

Stage 2 - Component Assembly from Factory to Construction Site

4-week construction process

For a 4-story scale

Prefabricated Column, Floor, Beam, Wall structures

The construction of the remaining parts of the prefabricated house, from the ground floor upwards, is very fast, especially within one or two months. While the foundation work is underway, all components for the entire project are manufactured at the factory, then transported and installed on-site. We estimate the on-site assembly process for a project to be within 4 weeks.

Adding the previous 1-2 months for foundation construction, KGM Vietnam guarantees that the entire rough construction phase can still be completed within two and a half to three months. Depending on the requirements and total project area, KGM Vietnam aims to complete projects within four months for areas up to 2,000 to 3,000 m2.

We constantly pioneer in updating technology to develop prefabricated house technology that brings efficiency to customers.

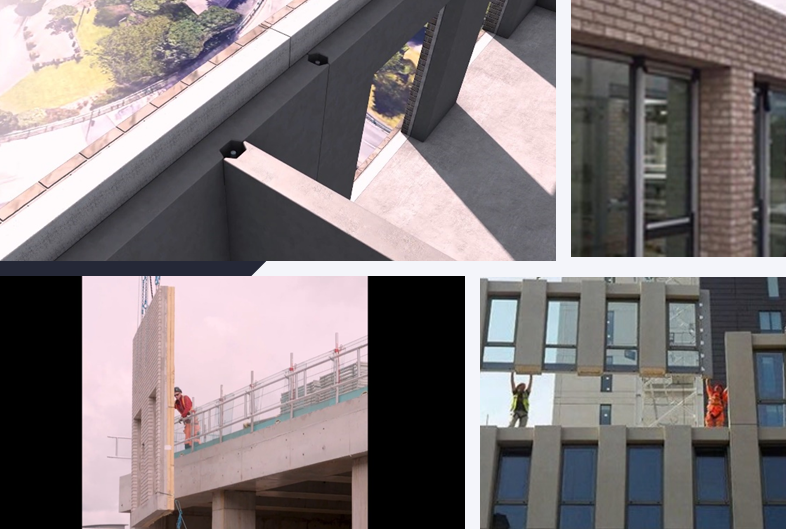

Stage 3 - Finishing Works

KGM Vietnam is collaborating with factories to develop vertical surfaces and facades, as well as the entire exterior architectural finishing, all completed at the factory. This includes decorative tile cladding, ensuring quality and safety for high-rise buildings, and saving costs while considering environmental materials. We will manufacture everything at the factory, so that while the rough construction is underway, the finishing components are also completed and ready for on-site installation.

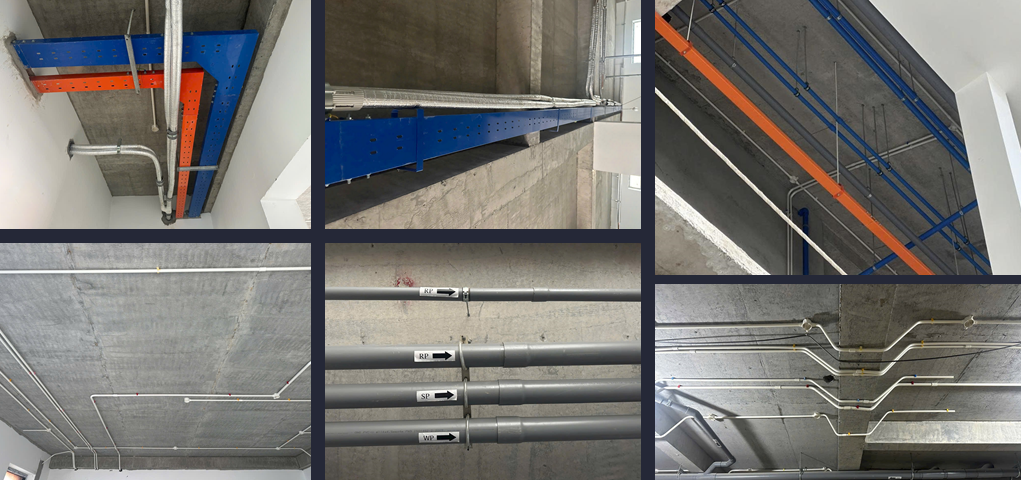

Stage 4 - MEP System Installation

Our MEP (mechanical, electrical, plumbing) components are also calculated according to drawings and integrated into the rough-in system very quickly and with high precision.

Stage 5 - Interior Decoration

Beyond finishing, interior decoration is also very important for a project.

All interior decoration items are also manufactured at our factory, so as soon as the rough construction is complete, we have the pre-produced furniture ready for installation.

The construction time for a project, from design to complex basement foundation work, rough basic construction, and finishing, is something KGM Vietnam is striving to optimize. We aim for a turnkey handover, from design and construction to interior manufacturing and final project delivery, in approximately four months or even faster.

We are upgrading all stages, supporting suppliers, support lines, and manufacturing factories.

Completed Prefabricated Projects

We aim to deliver a turnkey project to our clients that is more economical, faster, safer, and of consistently high quality, meticulously executed from design to construction.

To provide clients with a project offering a lifespan of up to 50 years or more, this is KGM Vietnam's criterion to always accompany customers and expand future developments.

Where to Find a Reputable Prefabricated House Contractor?

Finding a reputable contractor is a crucial factor determining the success of a prefabricated house project. A reputable firm will ensure everything from project quality to construction progress, meeting the owner's needs and desires.

See more: KGM Vietnam & Zak World Of Facades Vietnam Conference

In major cities like Ho Chi Minh City, selecting a construction contractor requires considering several important criteria to ensure quality and safe projects. KGM Vietnam has established itself as one of the leading contractors with over 15 years of experience in villa and residential housing construction and design.

Criteria for Choosing a Reputable Prefabricated House Contractor in Ho Chi Minh City

When choosing a construction contractor, several key criteria should be considered, such as:

Why Choose KGM Vietnam as Your Prefabricated House Contractor?

KGM Vietnam is a professional contractor with over 15 years of experience in the construction industry in Vietnam. We stand out not only for our reputation but also for ensuring high quality and advanced technology. The company always prioritizes customer benefits and does not subcontract.

KGM Vietnam pioneers prefabricated houses that are faster, smarter, safer, and offer durability for up to 50 years. With a team of well-trained engineers and workers, coupled with investment in modern equipment, we are committed to delivering sustainable and aesthetically pleasing projects.

Conclusion

Prefabricated houses are gradually becoming a new trend in construction, offering superior benefits in terms of time, cost, and flexibility. They are not only a fast and convenient construction solution but also an ideal choice for eco-friendly projects. Let KGM Vietnam accompany you in creating the living spaces of the future!